Plans for an Information Philosophy Institute

Design and Building (August 16, 2018)

We collect all our thoughts in a single document so general contractors can understand the full scope of possible work.

But we divide the work into phases so a single contractor could take full responsibility for a given phase or project element (e.g., the new door and stair).

One general contractor has now given us a budget estimate for taking on this project ($230,000 to $300,000). Although some specialists have shown interest in parts of the project, only one has given us a budget and time estimate, for a bathroom shower wall without a sliding door ($10,000, will be done in one day, two months from signed contract).

At this point, critical next steps are

-

a new heating system

-

new interior and outer wall framing and drywall

-

removable ceiling panels to access electrical circuits and low-voltage studio wiring

-

new front door/stair and remodeled back stair

-

remodel basement bathroom and new kitchenette

-

new guest rooms.

We will start to look for specialists to work on steps 2-6.

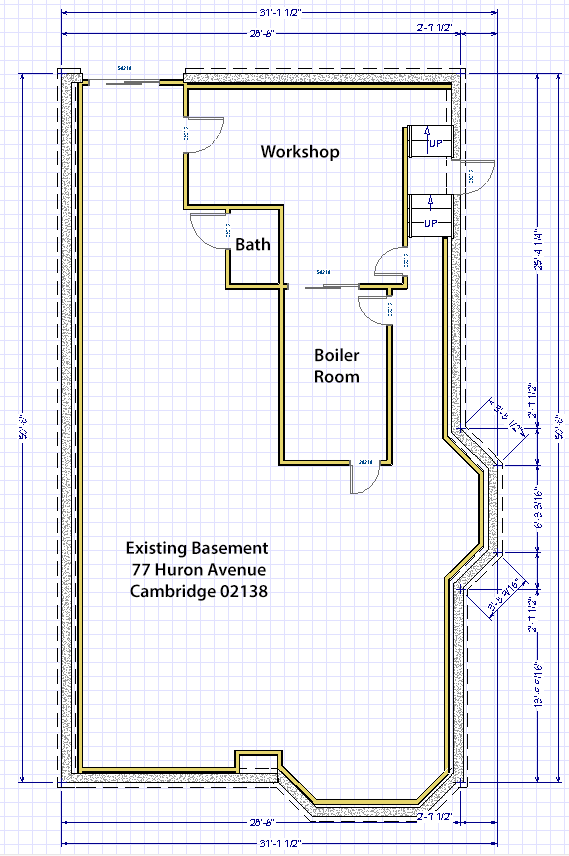

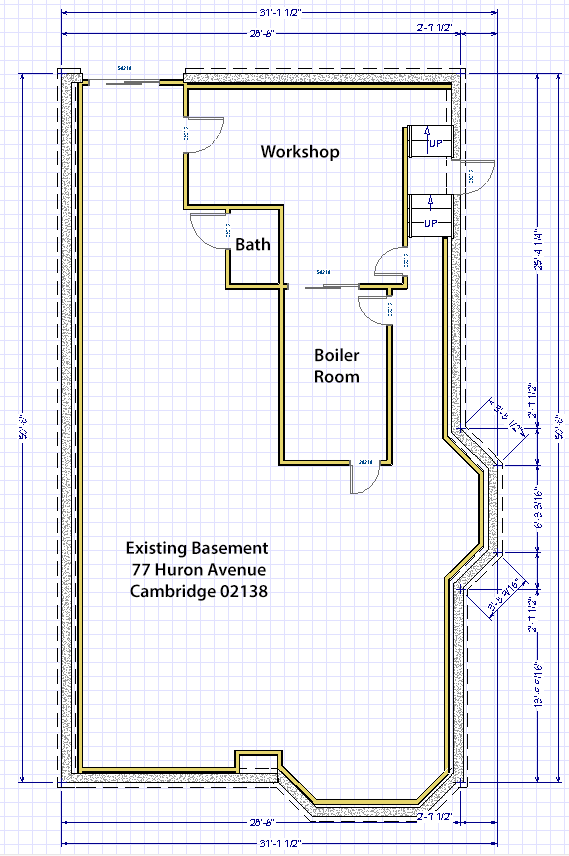

Phase 1, Demolition of Boilers-Pipes-Radiators, Ceilings, and Walls,

We decided to do the demolition phase ourselves to get a good look at any problems and we found significant damage hiding behind the walls and ceilings.

The basement had a horsehair plaster and lathe ceiling attached to floor joists, then a drop ceiling suspended a few inches below. The plaster had been pierced to install fluorescent lighting up between the joists. Plaster was crumbling and falling down in many places, making the basement dusty and dirty.

Steam pipes were too low for normal headroom. We decided to switch from steam heat to forced hot water.

Electrical wires, thirty Merlin PBX wires, doorbell wiring, and many other wires criss-crossed the cellar, lying on the ceiling tiles and randomly breaking through the plaster, which was constantly disintegrating into dust.

The oldest electrical wires were deteriorating cloth-insulated inside ancient BX metal armor.

Low-voltage electronics cables from our webcasting studio to the switcher and green room were very difficult to manage.

To get a clear look at floor joists and first-floor planking, we decided to remove the drop ceiling and demolish the plaster and drop ceilings. The drop ceiling averaged about 4" below the joists, reducing ceiling height below seven feet.

With all joists exposed, we did a survey of ceiling heights. In the front corners the height to the joists is 7'4" and averaged 7'3" across the space toward the outer walls. The main beams in the center are typically 7'1". We thought we might have to dig out the concrete floors, but that is now not necessary.

We plan to install 1/2" ceilings, removable plywood panels, and thin vinyl sheet flooring, so will have the Massachusetts state building code basement ceiling height everywhere. See code below.

There was no blocking between the joists, so at many places floorboards were spongy and noisy, pulled loose from the sub-floor.

We removed all of the BX and any obsolete wires, many of which were wrapped over and under pipes and haphazardly stapled to beams and joists with non-insulated staples. We reorganized locations for wires, attaching them neatly with insulated staples. Wires now run only down the long corridor between the main beams, then out between the joists.

This also provides us clear open paths for PEX-A piping between the main load beams and up between the floor joists for a new forced hot water heating system in phase 2.

We removed two inefficient steam boilers, many cast-iron black pipes, and 17 very heavy radiators from the three upper floors.

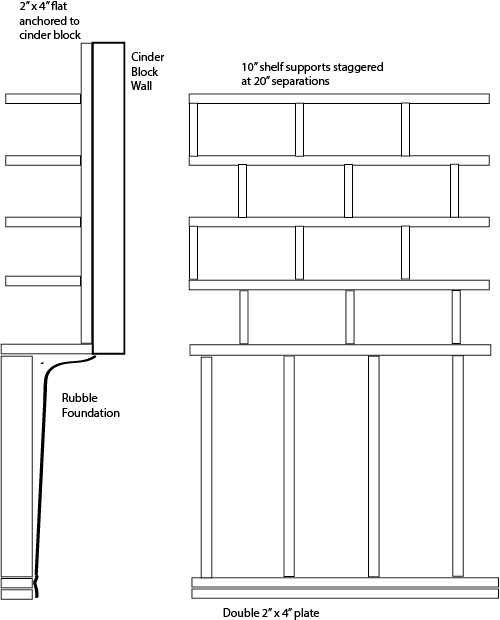

We have finished removing the sheetrock outer walls, studs, etc. Some studs and many 2" x 4" bottom plates were badly rotted.

We demolished the existing interior walls that must be moved to new places for the new boiler room, larger bathroom, and for the new workshop wall.

We removed the old vinyl floor tiles in preparation for new flooring. The concrete floor is uneven by as much as an inch, so we probably must flatten it (though not level it) for new floor tiles.

We demolished the walls and ceiling of the first floor bathroom, partly to run new drain pipes that do not compromise our new joists, and because we want to install a walk-in shower.

Phase 1a, Sistering Joists and Replacing Parts of Main Beams

We found water and termite damage to the back ends of main beams and several joists below the upper-floor bathrooms. Plumbers had cut deeply into the joists to position the bathtub drains and upper floors were sagging well below their original level.

We consulted a structural engineer whose report said that weak joists should be sistered with new 2" x 8" LVL planks. For the weakened main beams, he recommended removing them and installing three new 2" x 10" LVL boards to replace the bad beams. We used six 10-ton hydraulic jacks to shore up the joists, taking weight off the beams, so we could cut them into small pieces.

We are fastening the three LVL boards together with structural screws, construction adhesive, and through-bolted every 1.5 feet with 1/2" x 10" bolts.

Under the main beams we are putting more closely placed jack posts inside new wall partitions. Original columns were on 6' centers. New Tiger J-Pro-100 10-ton jack posts are on 2' centers between old columns. Support will be many times better than the original.

We got an extravagant estimate ($69,000) for sistering ten joists, replacing 20 feet of each main beam, and adding two new columns with new reinforced concrete footings. We got a lower estimate for just sistering the joists ($10,000), but still very expensive.

So we went ahead and sistered the seven worst joists ourselves, strengthening the "cripple box" around the plumbing stack. We have replaced 20 feet of one beam with three 2" x 10" LVL lumber, each pair screwed together with Headlok 2 3/4" screws and glued with Liquid Nails Extreme. The three planks are bolted together with 1/2" bolts every 1.5 feet.

We will replace one Lally column which has rust damage to the steel near its base, add two new columns with new concrete footings to be located in interior walls, and remove one column that obstructs the new kitchen counter area.

We repointed the lower half of exterior walls (rubble foundation) with new mortar, but this did not stop the water.

With all the exterior walls now visible, we ran water through a garden hose around the house perimeter and saw water coming through the rubble foundation in some places. We may need to dig outside and waterproof the foundation walls from the outside.

A new forced hot water heating system will be installed in about half the space of the old boiler room.

Gas entrance pipes need to be relocated up between the now-open joists, and boxed along the exterior wall.

Fire retardant walls and ceiling for the boiler room? Maybe not, because new boilers have sealed combustion chambers with no open flames.

System should have zone control for the three upper floors and for future basement and garage heating.

About 17 new European style, white wall-mounted radiators will be installed on the upper three floors.

Wirsbo/Uponor AquaPEX (PEX-A) piping will mostly follow the existing holes for the old steam radiators. We hope to hide most piping inside partitions.

Replace the hot water heater with an indirect tank with heat exchanger in the boiler.

Manifolds needed

-

5-loop master manifolds (supply and return) in boiler room with programmable flow actuators. (Size? 1 in. input, 3/4 out?)

-

Three 5-loop manifolds (e.g., 3/4 in, 1/2 out?), one for each floor, mounted above corridor between main beams with flow restrictions and home runs to radiators. Front/middle bedrooms, and rear bedroom/bath share a home run. Large front rooms have two. Kitchen has one.

-

Thermostatic valves on all radiators to balance room temperatures beyond flow restrictions?

Phase 2a, Sump Pumps to Prevent Flooding

Two sump pumps at the front are needed to eliminate future floods?

Although the cellar has been mostly dry since we redirected rain from our adjacent garages, we will install two sump pumps at the front left and right corners of the basement, with PVC pipe sending the water to our driveway, just as our neighbors at 81 Huron have done for years.

The one at left front should pipe over to that at the right, which should pump out to the common driveway, as our neighbor at 81 Huron now does.

We will also add new downspouts on porches at front and rear to keep water away from the house foundation.

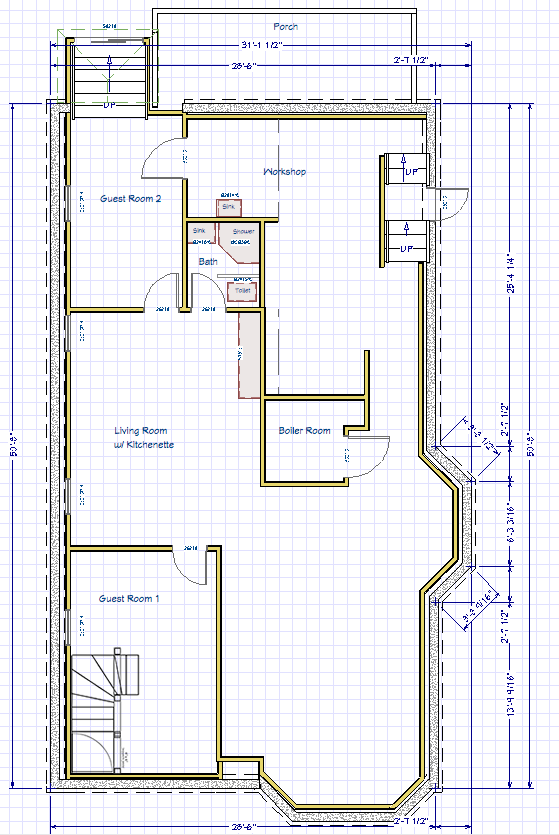

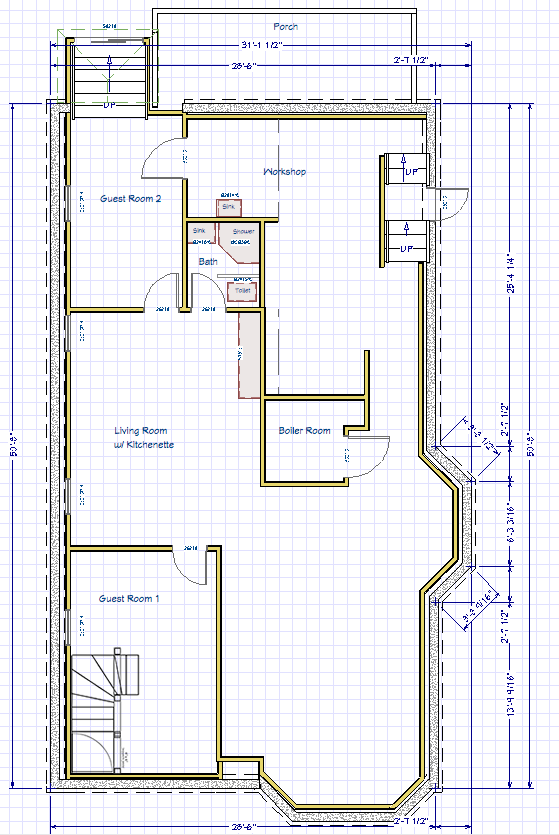

Phase 3, New Front and Renovated Rear Entrances, Renovate Bathroom, Add Kitchenette

- New door and stair at front of the basement, opening on the driveway, to provide another safe egress. Structural engineer is needed to approve framing to support the existing staircase above.

- Replace 6-foot sliding door at rear with a standard 80" door at the head of the stair (will need to remove concrete steps, replace with wood). We will house the new stairs inside the basement, surrounded by new exterior walls and roof, replacing existing open roof.

-

New double-pane casement hopper windows, with screens.

-

Renovate the existing half-bath to include a walk-in shower.

-

Leave existing Lally columns in the bathroom and workshop. Enclose one in a partition between shower and toilet. Add jack posts in bathroom and workshop walls to provide additional support for main beams.

-

Move existing workshop wall back to line up with bathroom, move the workshop sink.

-

Add a new kitchen sink and counter for kitchenette along the workshop wall. Space for microwave, convection oven, and small refrigerator.

-

Remove one Lally column that obstructs the kitchen counter. Add two new 3.5" steel tube columns, .220" wall with new footings and 6" x 6" top plate supporting the three 2" x 10" x 12' LVL planks through-bolted with 1/2" x 10" hex bolts.

-

Basement floor covering was vinyl tile. Instead of vinyl we need to flatten the concrete floor and install ceramic/porcelain planks that are waterproof, for example Daltile Glenwood Fog 7 in. x 20 in. Ceramic Floor and Wall Tile.

Phase 3a, Renovate Two Upper Floor Bathrooms

New walk-in showers, replace leaking pipes on floors 1 and 3.

Add sister joists to strengthen those badly cut away for cast iron pipe access below first floor bath. Thread new PVC piping through holes, not notches, in the new sistered joists, or perhaps in the first floor bathroom wall.

We demolished the walls and ceiling of the first floor bathroom and will build a new stud wall at 60" separation to accept a new walk-in shower.

Proposed fixtures for first floor bathroom.

We hope to cut the 0.2" wall material to allow us to keep the window.

Phase 4, New Ceiling, Outer Walls, Renovate Bath, and Partitions for Two Guest Rooms in Basement

Phase 4a. Front Stair Design

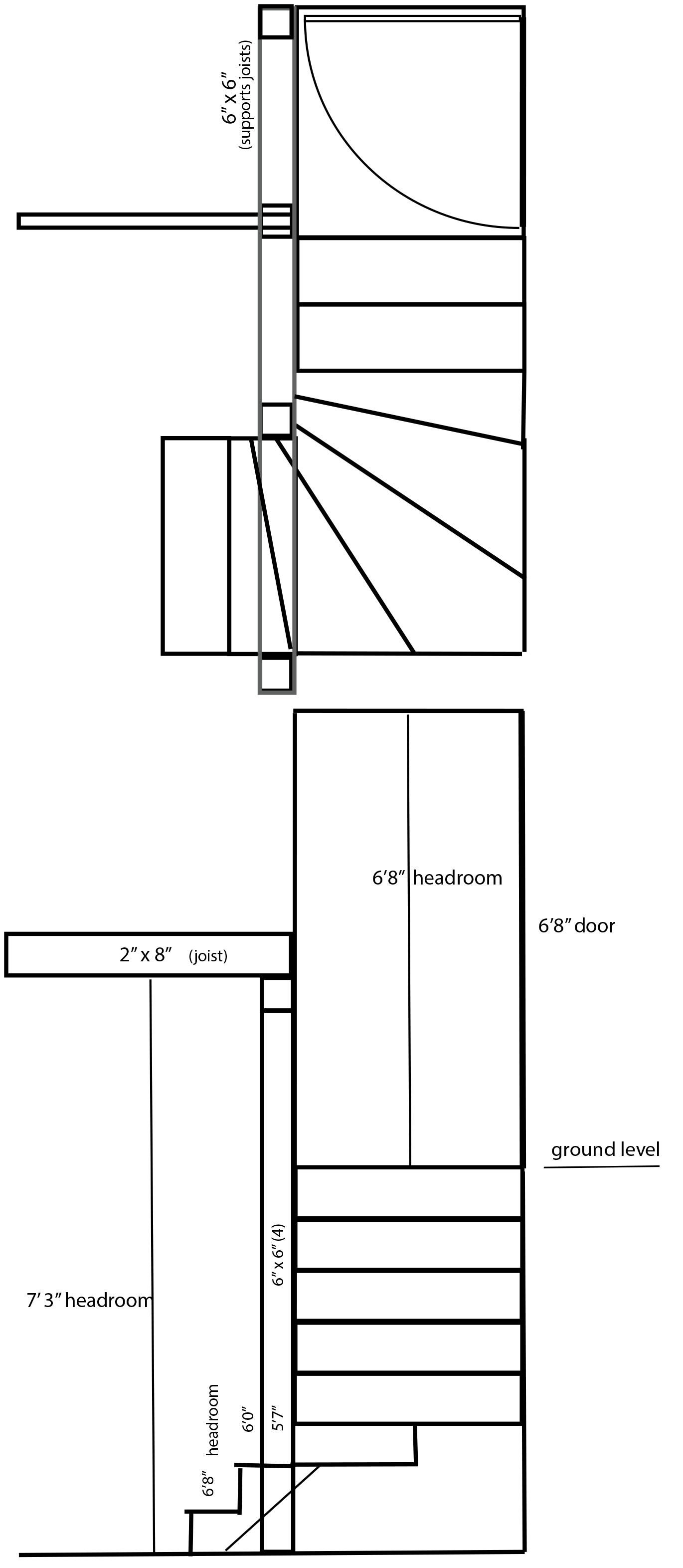

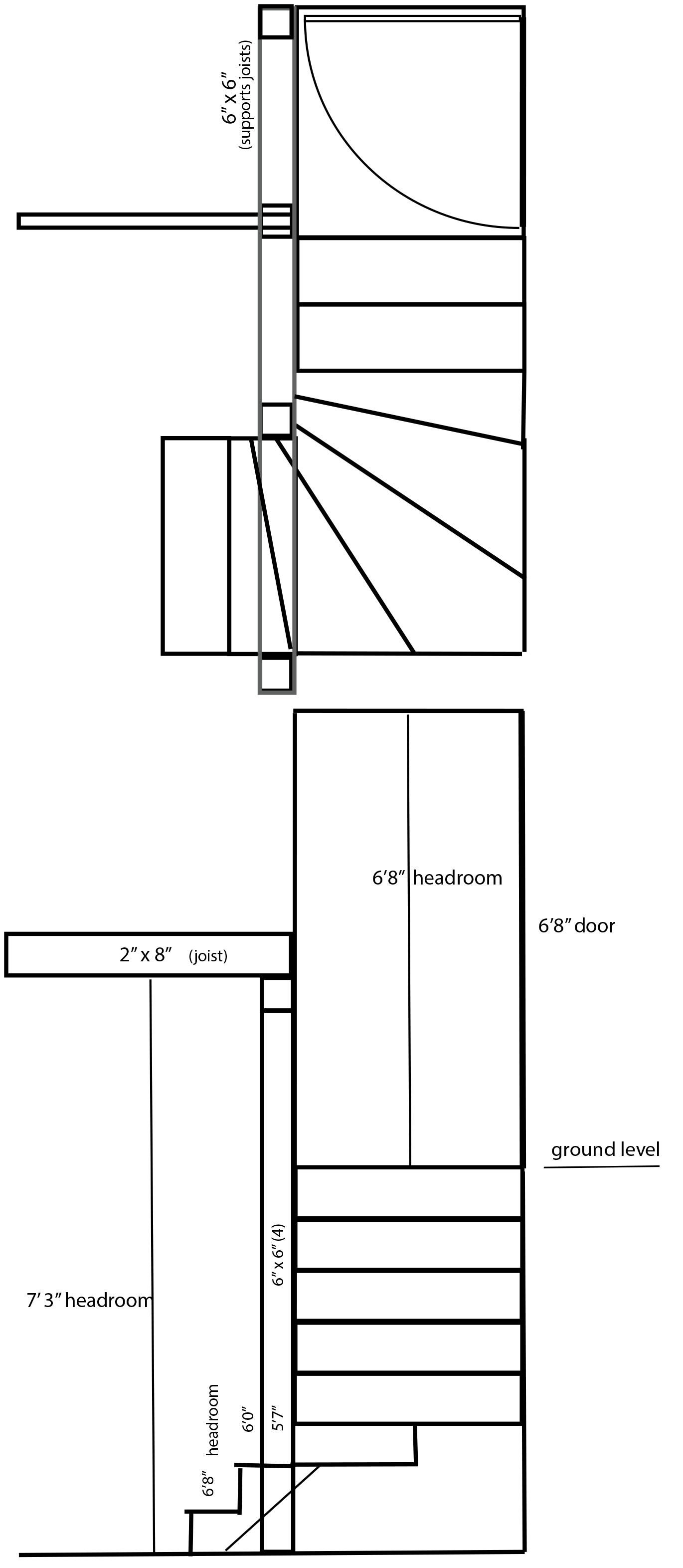

Visualization of new side entrance

The front stair follows the same arrangement of treads as the stairs above to maximize headroom. Because its landing is a few feet below the vestibule of the first floor, it has only one winding and eight stairs instead of 13 in the upper floors.

Since the basement ceiling height is 7'3" at the new stair, compared to upper floors with nine feet, the headroom may be below code, depending on access to the under stair space above. It is lowest at the winder corner, 5'7".

While upper floor winder stairs have zero tread width at the inner corner, this design maintains average tread width of 10" along the center line of travel per modern code.

Headroom is reduced at that corner by the new beam holding up the crippled joists. Could we push that beam farther away from the outer wall to get the necessary headroom? We need to inspect the space under the first flight of stairs above. Maybe headroom will be over 6'.

Visualization of new side entrance

The front stair follows the same arrangement of treads as the stairs above to maximize headroom. Because its landing is a few feet below the vestibule of the first floor, it has only one winding and eight stairs instead of 13 in the upper floors.

Since the basement ceiling height is 7'3" at the new stair, compared to upper floors with nine feet, the headroom may be below code, depending on access to the under stair space above. It is lowest at the winder corner, 5'7".

While upper floor winder stairs have zero tread width at the inner corner, this design maintains average tread width of 10" along the center line of travel per modern code.

Headroom is reduced at that corner by the new beam holding up the crippled joists. Could we push that beam farther away from the outer wall to get the necessary headroom? We need to inspect the space under the first flight of stairs above. Maybe headroom will be over 6'.

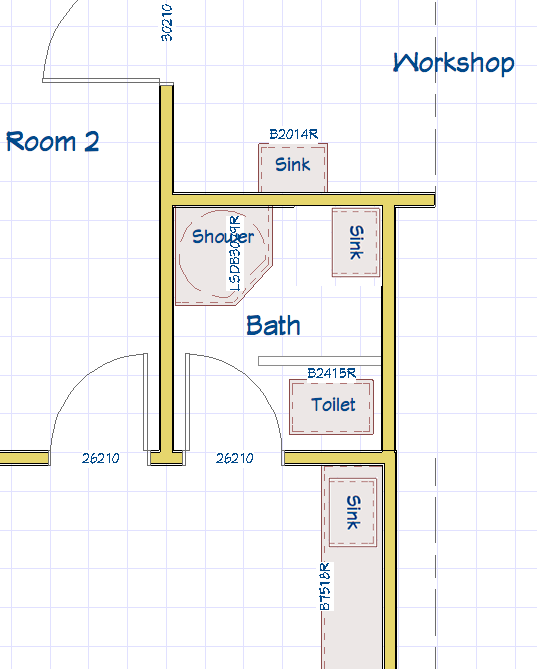

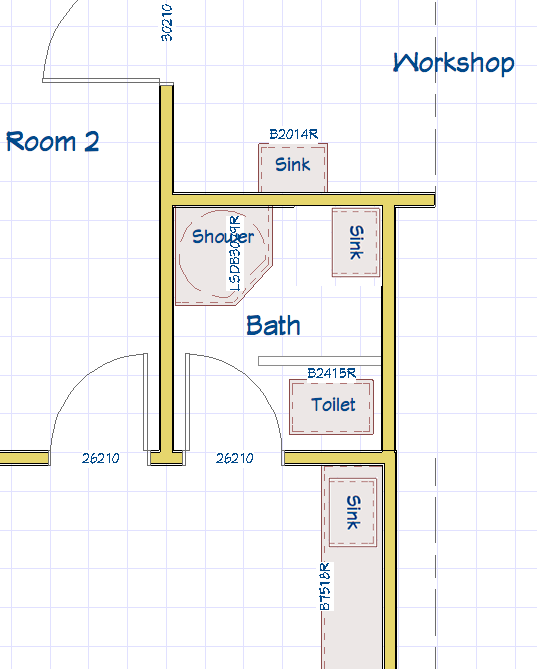

Phase 4b. Renovate Basement Bathroom

Enlarge bath from 7' x 3.5' to 7' x 6'.

Existing plumbing works well for toilet and sink.

Probably need to excavate part of bathroom floor to provide a P-trap for a new shower drain. Also will need a sump pump to force shower water up into adjacent sink drain? An "ejector" pump is not needed because shower drain has no solid waste.

Proposed fixtures.

Cambridge Zoning Standards and 77 Huron Avenue

Our property is non-conforming with multiple zoning standards from

ZONING ORDINANCE - CITY OF CAMBRIDGE

ARTICLE 5.000 DEVELOPMENT STANDARDS,

5.31 Residential Districts

|

District

|

1. Max. Ratio of Floor Area to Lot Area (FAR)

|

2. Min. Lot Size

|

Min. Lot Area for each D.U. in Sq. Ft.

|

Min. Lot Width in Feet

|

Minimum Yard in Feet

|

Front

|

Side

|

Rear

|

|

Max. Height in Feet

|

Min. Ratio of Private Op. Sp. to Lot Area

|

|

Res. B

|

0.5

|

5,000

|

2,500

|

50

|

|

35

|

40%

|

|

77 Huron

|

1.16

|

3745

|

3745/3 = 1248

|

40

|

|

35

|

53%

|

Excerpt from Cambridge Property Database for 77 Huron Avenue

Property Value

| Year of Assessment | 2018 |

|---|

| Tax District | R6 |

|---|

| Residential Exemption | Yes |

|---|

| Building Value | $799,800 |

|---|

| Land Value | $845,300 |

|---|

| Assessed Value | $1,645,100 |

|---|

| Sale Price | $42,500 |

|---|

| Book/Page | 12493/ 731 |

|---|

| Sale Date | August 3, 1973 |

|---|

| Previous Assessed Value | $1,604,400 |

|---|

Owner Information

| Owner(s) | DOYLE, ROBERT D. &

HOLLY THOMIS DOYLE

77 HURON AVE

CAMBRIDGE, MA 02138-6798 |

|---|

Building Information

Residential Building Number 1, Section 1

Exterior

| Style | DECKER |

|---|

| Occupancy |

THREE-FM-RES |

| Number of Stories | 3 |

|---|

| Exterior Wall Type |

Wood Shingle |

| Roof Type |

Flat |

| Roof Material |

Rubber Membrane |

Interior

| Living Area (sq. ft.) | 4,362 |

|---|

| Number of Units |

3 |

| Total Rooms |

18 |

| Bedrooms |

9 |

| Kitchens |

3 |

| Full Baths |

3 |

| Half Baths |

1 |

| Fireplaces |

0 |

Systems

| Heat Type | Steam |

|---|

| Heat Fuel |

Gas |

| Central A/C |

No |

Condition & Grade

| Year Built | 1916 |

|---|

| Interior Condition |

Average |

| Overall Condition | Average |

|---|

| Overall Grade | Good |

|---|

Parking

| Open Parking | 2 |

|---|

| Covered Parking | 0 |

|---|

Subareas

| Code |

Description |

Gross Area |

Living Area |

| FOP |

Porch, Open |

651 |

0 |

| FUS |

Upper Story, Finished |

2,908 |

2,908 |

| BAS |

First Floor |

1,454 |

1,454 |

| FBM |

Basement, Finished |

700 |

0 |

| UBM |

Basement |

754 |

0 |

| Total: |

6,467 |

4,362 |

Ceiling Height - Code of Massachusetts Regulations

CMR: STATE BOARD OF BUILDING REGULATIONS AND STANDARDS

780 CMR 5305 CEILING HEIGHT 5305.1 Minimum Height. Habitable rooms, hallways, corridors, bathrooms, toilet rooms, laundry rooms and basements shall have a ceiling height of not less than seven feet (2134 mm). The required height shall be measured from the finish floor to the lowest projection from the ceiling.

Exceptions:

1. Beams and girders spaced not less than four feet (1219 mm) on center may project not more than six inches (152 mm) below the required ceiling height.

2. Ceilings in basements without habitable spaces may project to within six feet, eight inches (2032 mm) of the finished floor; and beams, girders, ducts or other obstructions may project to within six feet, four inches (1931 mm) of the finished floor.

3. Not more than 50% of the required floor area of a room or space is permitted to have a sloped ceiling less than seven feet (2134 mm) in height with no portion of the required floor area less than five feet (1524 mm) in height.

4. Bathrooms shall have a minimum ceiling height of six feet eight inches (2036 mm) over the fixture and at the front clearance area for fixtures. A shower or tub equipped with a showerhead shall have a minimum ceiling height of six feet eight inches (2036 mm) above a minimum area 30 inches (762 mm) by 30 inches (762 mm) at the showerhead.

5. Ceiling heights in habitable basements, including drop ceilings, shall be a minimum of six feet eight inches (2032 mm).

References

This Old House

Stair Construction

Visualization of new side entrance

The front stair follows the same arrangement of treads as the stairs above to maximize headroom. Because its landing is a few feet below the vestibule of the first floor, it has only one winding and eight stairs instead of 13 in the upper floors.

Since the basement ceiling height is 7'3" at the new stair, compared to upper floors with nine feet, the headroom may be below code, depending on access to the under stair space above. It is lowest at the winder corner, 5'7".

While upper floor winder stairs have zero tread width at the inner corner, this design maintains average tread width of 10" along the center line of travel per modern code.

Headroom is reduced at that corner by the new beam holding up the crippled joists. Could we push that beam farther away from the outer wall to get the necessary headroom? We need to inspect the space under the first flight of stairs above. Maybe headroom will be over 6'.

Visualization of new side entrance

The front stair follows the same arrangement of treads as the stairs above to maximize headroom. Because its landing is a few feet below the vestibule of the first floor, it has only one winding and eight stairs instead of 13 in the upper floors.

Since the basement ceiling height is 7'3" at the new stair, compared to upper floors with nine feet, the headroom may be below code, depending on access to the under stair space above. It is lowest at the winder corner, 5'7".

While upper floor winder stairs have zero tread width at the inner corner, this design maintains average tread width of 10" along the center line of travel per modern code.

Headroom is reduced at that corner by the new beam holding up the crippled joists. Could we push that beam farther away from the outer wall to get the necessary headroom? We need to inspect the space under the first flight of stairs above. Maybe headroom will be over 6'.